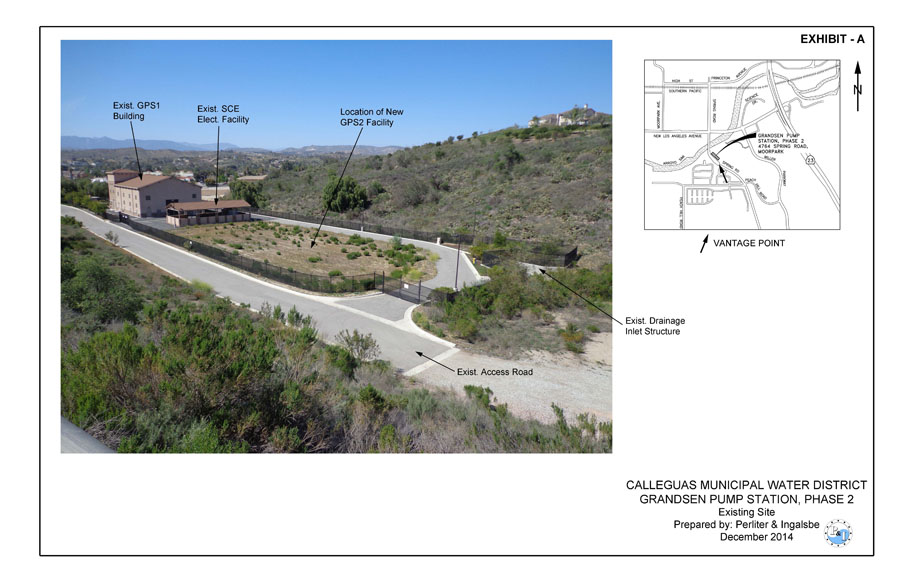

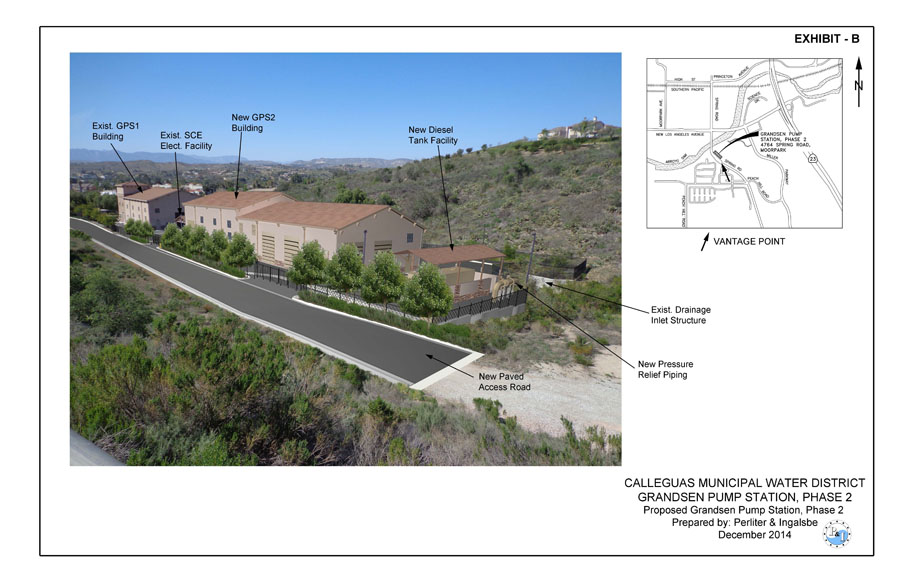

Standby Diesel Generators at Grandsen Pump Station:

- Owner: Calleguas Municipal Water District

- Cost: Project Cost - $20,500,000, Cost of Generators and Associated Facilities - $8,500,000 (estimated)

Grandsen Pump Station site is a vital component of a larger and complex project known as Las Posas Basin Aquifer Storage and Recovery which was launched by CMWD in 1995. The pump station site is comprised of numerous major components, including five pumps with 56,000 gpm flow capacity. 4160VAC motors with total HP rating of 2900, two pressure regulating stations with 36,000 gpm flow capacity, two hydro generators capable of producing with 400 KW of electric power, 6" through 72" pipes, HVAC systems, buildings, cranes, electrical equipment and system, and many more components.

The pump station will provide water to Owner's eastern and western service areas comprised of many cities and districts during periods when imported water from Metropolitan Water District (MWD) is not available during maintenance and repair work of MWD's system. It is critical that the pump station remains operational during such time to provide continuous water. To ensure that it also remains operational during electrical power outages, standby diesel generators are considered to power all critical components at the site.

Perliter & Ingalsbe determined the required number and sizes of diesel generators, performed final design of the generator and associated mechanical, civil, electrical and structural components.

The project is expected to be under construction in February 2016.

Major Components and Special Features:

- Two 2.5 MW, 4160VAC diesel operated generators to power the facility components, including:

- Two 1,500 HP - 4,160 VAC pumps/motors

- Two 350 HP - 4160VAC pumps/motors or

- One 700 HP - 4160VAC pump/motor

- Five 4,160VAC VFDs

- Electrical switchgears and panel boards

- 30 ton air conditioning system

- Two 10-ton cranes

- Roll-up doors and entrance gate

- Lights and receptacles

- Instrumentation and controls

- PLCs, alarms, and signals

- One 500 KW, 480VAC diesel generator to power all critical loads at the site including:

- 480VAC switchgear and power system

- 240/120 switchboard and power system

- 30 ton air conditioning system

- Two 10-ton cranes

- Roll-up doors and entrance gate

- Lights and receptacles

- Instrumentation and controls

- PLCs, alarms, and signals

- Generator appurtenances and auxiliary devices

- Paralleling switchgear, 4160VAC

- Automatic transfer switches

- Generator testing tap box

- 12,000 gallon diesel storage tank

- Three day tanks (one for each generator)

- Diesel fuel filtration and recircliating system

- Masonry building with special architectural treatment

- Sound attenuating devices, including silencers and sound absorbing panels

- Controls and instrumentation